Marine fenders are essential protective devices used in berthing and mooring operations to absorb kinetic energy and prevent damage to vessel hulls, berths and offshore structures. Designed and manufactured for reliability in harsh marine environments, Nordic Fender’s range includes high-performance pneumatic fenders, foam filled fenders and fixed fender solutions that meet industry standards and support safe, efficient maritime operations.

Pneumatic fenders

Nordic Fender’s Pneumatic Fenders deliver strong energy absorption and reliable protection for any berthing or STS operation.

Not sure which fender sizes or quantities you need?

Use our calculation tool to quickly find the right solution for your operation. Access the tool here.

Click here to read more about our Pneumatic fenders

ISO 17357-1:2014 sets the requirements for materials, performance, dimensions, and testing of high-pressure pneumatic fenders used for ship-to-ship and berthing operations. Nordic Fender’s Pneumatic Fenders are fully compliant with this standard, delivering high performance and durability for safe and efficient operations.

Our types:

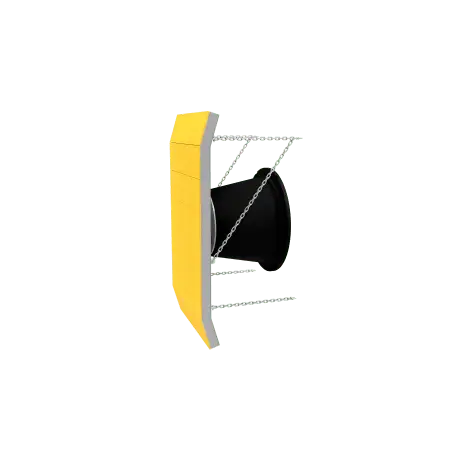

- Sling fenders (S)

- Chain & tyre net fenders (C)

- Hydro pneumatic fenders

- See stock.

| Type | 50 kPa | 80 kPa | Diameter (mm) | Length (mm) | Weight (kg) | Energy abs (kNm) | Reaction force (kN) | Inquiry |

|---|---|---|---|---|---|---|---|---|

| NF-P-0510-50-S | Data sheet | Data sheet | 500 | 1000 | 37 | 6 | 64 | Click here |

| NF-P-0715-50-S | Datasheet | Data sheet | 700 | 1500 | 65 | 17 | 137 | Click here |

| NF-P-0815-50-S | Data sheet | Data sheet | 800 | 1500 | 83 | 20 | 146 | Click here |

| NF-P-0815-50-C | Data sheet | Data sheet | 800 | 1500 | 249 | 20 | 146 | Click here |

| NF-P-1015-50-S | Data sheet | Data sheet | 1000 | 1500 | 120 | 32 | 182 | Click here |

| NF-P-1015-50-C | Data sheet | Data sheet | 1000 | 1500 | 286 | 32 | 182 | Click here |

| NF-P-1020-50-S | Data sheet | Data sheet | 1000 | 2000 | 146 | 45 | 257 | Click here |

| NF-P-1020-50-C | Data sheet | Data sheet | 1000 | 2000 | 324 | 45 | 257 | Click here |

| NF-P-1220-50-S | Data sheet | Data sheet | 1200 | 2000 | 192 | 63 | 297 | Click here |

| NF-P-1220-50-C | Data sheet | Data sheet | 1200 | 2000 | 412 | 63 | 297 | Click here |

| NF-P-1325-50-S | Data sheet | Data sheet | 1350 | 2500 | 258 | 102 | 427 | Click here |

| NF-P-1325-50-C | Data sheet | Data sheet | 1350 | 2500 | 611 | 102 | 427 | Click here |

| NF-P-1525-50-S | Data sheet | Data sheet | 1500 | 2500 | 290 | 123 | 464 | Click here |

| NF-P-1525-50-C | Data sheet | Data sheet | 1500 | 2500 | 655 | 123 | 464 | Click here |

| NF-P-1530-50-S | Data sheet | Data sheet | 1500 | 3000 | 332 | 153 | 579 | Click here |

| NF-P-1530-50-C | Data sheet | Data sheet | 1500 | 3000 | 715 | 153 | 579 | Click here |

| NF-P-1730-50-S | Data sheet | Data sheet | 1700 | 3000 | 415 | 191 | 639 | Click here |

| NF-P-1730-50-C | Data sheet | Data sheet | 1700 | 3000 | 809 | 191 | 639 | Click here |

| NF-P-2030-50-S | Data sheet | Data sheet | 2000 | 3000 | 534 | 264 | 750 | Click here |

| NF-P-2030-50-C | Data sheet | Data sheet | 2000 | 3000 | 1328 | 264 | 750 | Click here |

| NF-P-2035-50-S | Data sheet | Data sheet | 2000 | 3500 | 594 | 308 | 875 | Click here |

| NF-P-2035-50-C | Data sheet | Data sheet | 2000 | 3500 | 1414 | 308 | 875 | Click here |

| NF-P-2540-50-S | Data sheet | Data sheet | 2500 | 4000 | 1080 | 663 | 1381 | Click here |

| NF-P-2540-50-C | Data sheet | Data sheet | 2500 | 4000 | 2266 | 663 | 1381 | Click here |

| NF-P-2555-50-S | Data sheet | Data sheet | 2500 | 5500 | 1325 | 943 | 2019 | Click here |

| NF-P-2555-50-C | Data sheet | Data sheet | 2500 | 5500 | 2840 | 943 | 2019 | Click here |

| NF-P-3050-50-S | Data sheet | Data sheet | 3000 | 5000 | 1705 | 1079 | 1903 | Click here |

| NF-P-3050-50-C | Data sheet | Data sheet | 3000 | 5000 | 3595 | 1079 | 1903 | Click here |

| NF-P-3345-50-S | Data sheet | Data sheet | 3300 | 4500 | 1770 | 1175 | 1884 | Click here |

| NF-P-3345-50-C | Data sheet | Data sheet | 3300 | 4500 | 3987 | 1175 | 1884 | Click here |

| NF-P-3365-50-S | Data sheet | Data sheet | 3300 | 6500 | 2225 | 1814 | 3015 | Click here |

| NF-P-3365-50-C | Data sheet | Data sheet | 3300 | 6500 | 5119 | 1814 | 3015 | Click here |

| NF-P-4570-50-S | Data sheet | Data sheet | 4500 | 7000 | 3660 | 3696 | 4470 | Click here |

| NF-P-4570-50-C | Data sheet | Data sheet | 4500 | 7000 | 8171 | 3696 | 4470 | Click here |

| NF-P-4590-50-S | Data sheet | Data sheet | 4500 | 9000 | 4380 | 4752 | 5747 | Click here |

| NF-P-4590-50-C | Data sheet | Data sheet | 4500 | 9000 | 10591 | 4752 | 5747 | Click here |

STS operation – mind the gap!

Foam fenders

Foam offers more flexibility as dimensions and performance characteristics can be customized according to type of project and specific requirements. There is no ISO standard as for the pneumatics, but design and manufacturing guidelines are given by PIANC.

Click here to read more about our Foam fenders

As with the rubber fenders the foam fenders can be floating in sea, fixed to quay or hanging from ship side. Different type of application requires different type of solution.

Chain type

Here we refer to «chain type» as in chain passing through the fender body, with a swivel arrangement at each end allowing the fender to rotate during operation. Typical sizes are from 0.7 diameter and up to 4m, with lengths from 1.2 to 12m. In addition we can supply foam fenders fitted with chain & tyre net. This will offer additional protection of the coating (outer layer) and foam core.

Steel type

The steel axle fenders are designed with connecting flanges and swivels mounted each end, allowing the fender to rotate. Typical sizes are from 0.8 diameter and up to 4m, with lengths from 1.2 to 12m.

PU type

The PU axle fenders have no metal parts, which eliminates risk for sparks and damage to hull/ship.This type is not designed for large sized ships or heavy duty operations. Sizes: from 0.3 diameter and up to 1.8m, with lengths from 0.7 to 3m.

System fenders

System fenders are complete, engineered fender systems used to protect port structures, quays, and berths from the impact of vessels.

Click here to read more about our System fenders

Unlike simple, standalone fenders (like a single pneumatic fender or a D-profile), a system fender is a combination of components designed to work together, usually including:

- Energy-absorbing fender body (cell, cone, arch, leg, etc.)

- Front panel (steel panel that distributes load)

- Facing pads (usually UHMW-PE, low-friction surface)

- Anchoring system (bolts, chains, fixings)

They are engineered per berth, often custom-sized for vessel type, berthing energy, tidal range, and quay layout.

Fixed fenders

Nordic Fender supplies all sorts of profile fenders, in rubber or foam/PU.

Click here to read more about our Fixed fenders

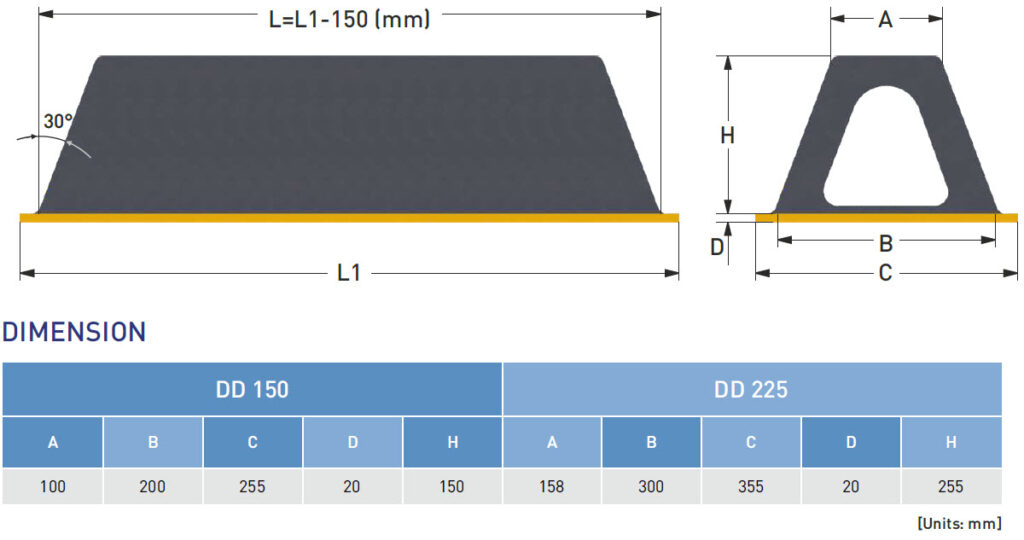

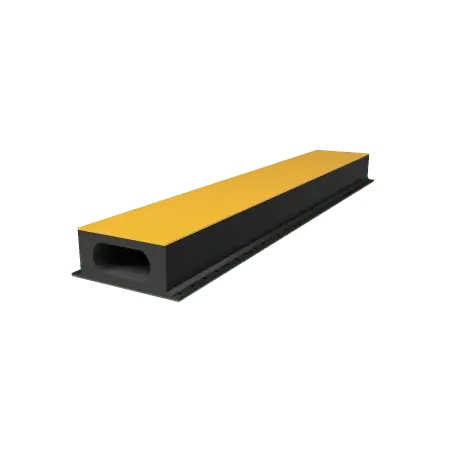

D Fender

Robust fender for many different applications such as quay walls and jetties, plus installed on vessels typically as a fender list. Can be delivered with D-bore or circular bore (O), cut to specific lengths and pre-drilled in case needed.

Cylindrical Fender

Probably the most common type to find in smaller ports and harbours around the world. Can also be used on ships for various type of operations. With the hollow cylindrical shape it easy to install, and with a range starting from 100 mm OD (diameter) up to 2500 it can be a good alternative for many different segments.

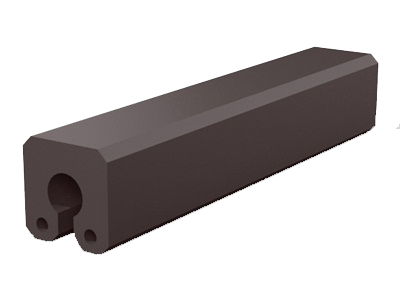

Keyhole Fender

Probably the most common type to find in smaller ports and harbours around the world. Can also be used on Common to find on tugs, installed in the bow and stern, offering proper protection for heavy duty operations. They are also seen on special installations such as ramps in ports, and pontoons. There are various optional features such as flat/ribbed face, solid block +.

W/M Fender

The W and M fenders are commonly used on tugs. These are moulded rubber units made to tolerate tough operations, with tugs using the bow and stern actively in the daily operations. Sizes from 320 mm to 500 mm.

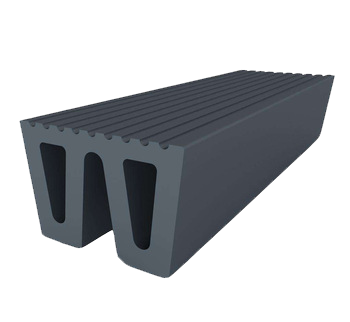

Element Fender

The element fender consist of legs, with internal steel mounting plates and concealed bolts. These are used in ports, and can be installed as a V fender with UHMW-PE pad or more complex arrangements.

Arch Fender

Arch fenders are either rubber faced or with UHMW-PE padding. Typical to find on quay walls, offering minimal maintenance and wide range of sizes are available. Can also be found on special ships such as FPSO, installed on specific area on the hull for protection of critical equipment.

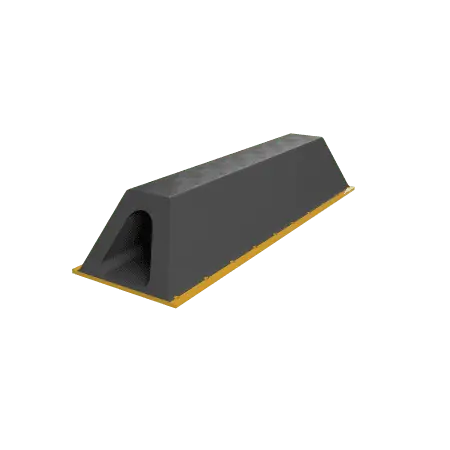

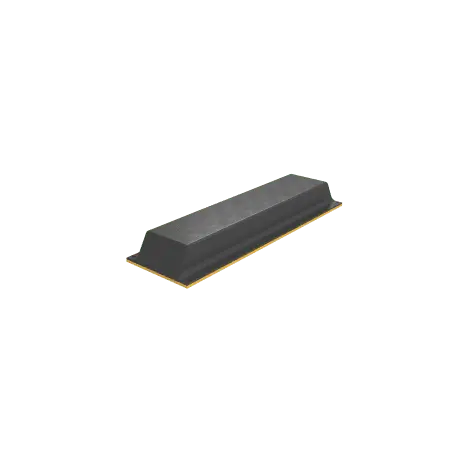

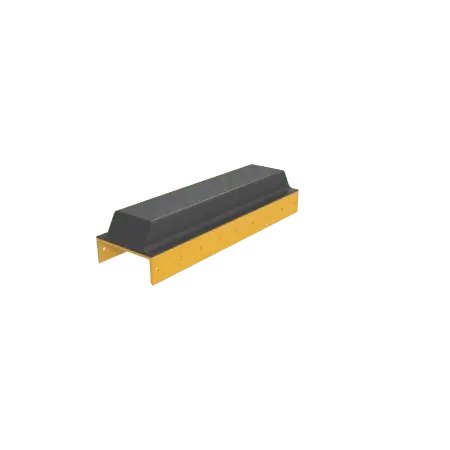

Rubbing strips

Rubbing strips are premium, abrasion-resistant rubber components with steel backing, designed for durability and robust performance. They serve to shield offshore jacket legs or boat landings from impacts and wear, significantly extending their lifespan. Engineered for harsh offshore conditions, these strips feature exceptional shear strength. Nordic Fender offers a range of rubbing strips tailored to different loads and applications.

Type of rubbing strips: Jacket leg rubbing strip, boat landing rubbing strips-type, boat landing rubbing strips (several types) and D-type boat landing rubbing fender. Read more in our next section; Offshore/Wind.

Offshore / wind

Our products are designed for the demanding conditions of wind and offshore operations, our fender solutions provide reliable protection where constant movement, harsh weather, and high operational loads are part of everyday work. From vessel landings to critical maintenance tasks, our products ensure safe, stable and efficient operations across modern offshore and wind installations.

Click here to read more about our products related to Offshore/Wind

Sway and surge fender

Surge and sway fenders are crucial in float-over operations for installing offshore topsides. They absorb impacts between the barge and offshore structure, preventing damage and limiting movement. Special rubber compounds are used for these applications.

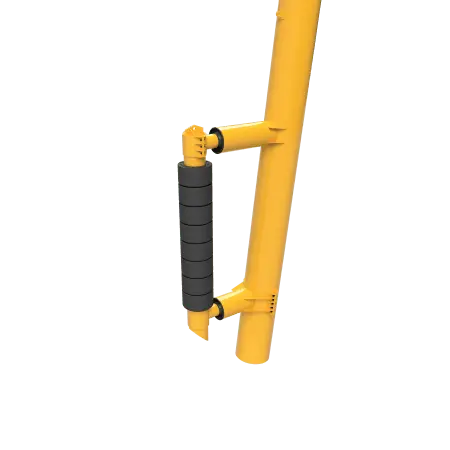

Bumper rings

Bumper Rings are an integral component of Barge Bumpers, designed to absorb and dissipate berthing energy while rotating on the Contact Post of the Barge Bumpers. This rotating action minimizes the shear force exerted by the rubbing of barges or boats during berthing. These rings are highly versatile, finding extensive application across various Barge Bumper Assemblies and configurations. Depending on specific duty requirements and operational conditions, Bumper Rings can be tailored to meet different functions and specifications. They can also be supplied in highly abrasive-resistant polyurethane rubber.

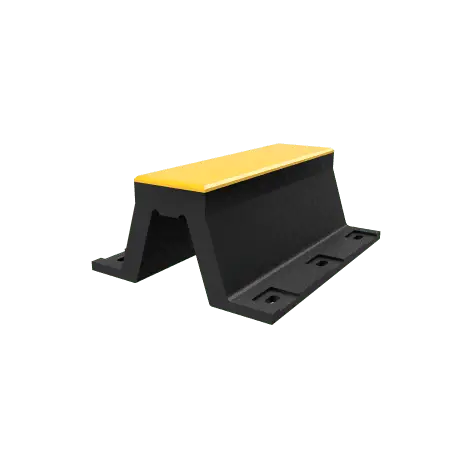

Barger bumpers

Barge bumper system is designed to absorb the berthing energy of barges and tugs at offshore rigs. The system consists of two shock cells and a bumper post with revolving rubber rings, which together allow for both axial and horizontal load absorption, making it ideal for challenging offshore conditions.

There are two types of barge bumpers: one with a basic shock cell and another with an eccentric bumper ring attached to the shock cell. The latter configuration reduces point load stress on the bumper post and steel components, supporting higher loads.

We also work with first class manufacturer of system fenders, for ports and terminals. We can offer a complete package and support – from initial project phase to final installation. Read more in our offshore section, here.

Rubbing strips

Rubbing strips are premium, abrasion-resistant rubber components with steel backing, designed for durability and robust performance. They serve to shield offshore jacket legs or boat landings from impacts and wear, significantly extending their lifespan. Engineered for harsh offshore conditions, these strips feature exceptional shear strength.

Features:

- Specially formulated low-friction rubber

- Custom backing plates that can be welded or bolted to the jacket leg

- Special UHMWPE bonded rubbing strip available

- Virtually maintenance free

- Easy to install

Applications:

- Offshore jacket legs

- Boat landing

- Jetty walls

- Jetty legs

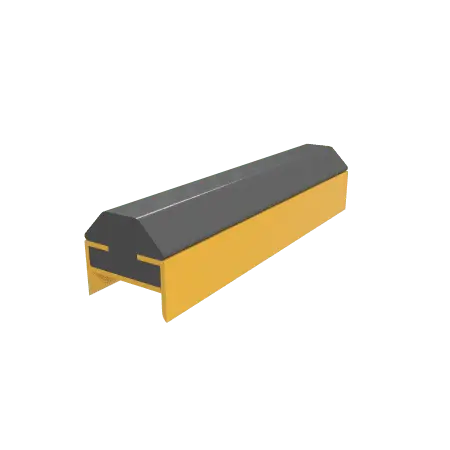

D-type boat landing rubber fender

Most frequently employed for boat landing applications on offshore platforms are D type boat

landing fenders. These fenders are composed of hollow, low-friction rubber in a D shape for

boat landing wear and tear applications. These fenders have the function absorbs the impact

load on the jacket structure. These fenders are very durable, reliable, and maintenance-free.

According to the boat landing design, these fenders are provided in a variety of lengths and

fitting configurations.

Photo: installation photo from customer.