Deck equipment is a critical part of a vessel’s operational safety and functionality. Properly designed and certified equipment ensures controlled load handling, safe mooring and towing operations, and reduced risk to crew and vessel.

Nordic Fender supplies deck equipment engineered for marine and offshore vessels operating in demanding environments. Our solutions are selected with a strong focus on strength, durability and compliance with applicable maritime standards, ensuring reliable performance throughout the vessel’s service life.

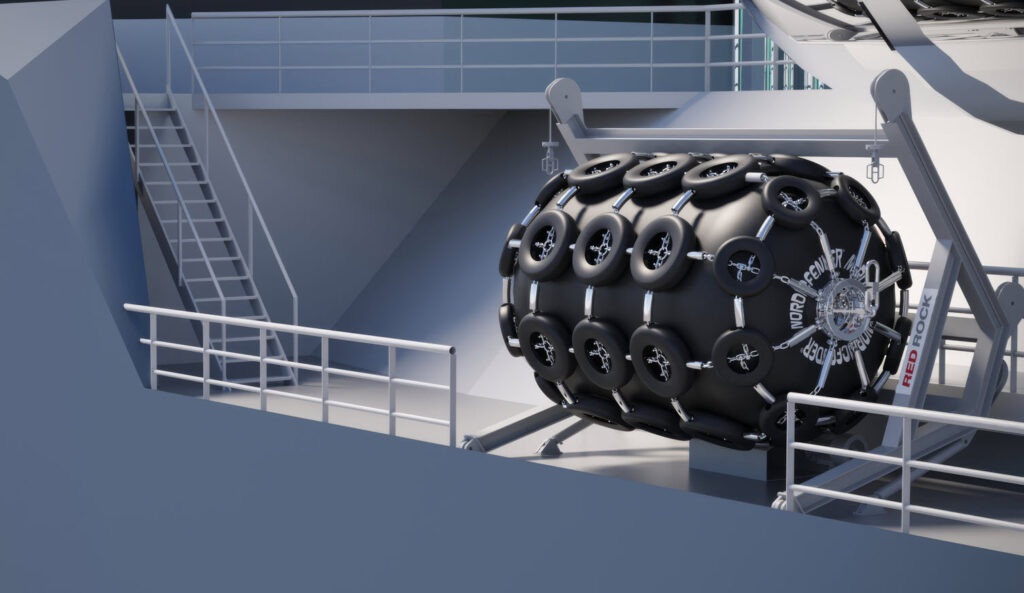

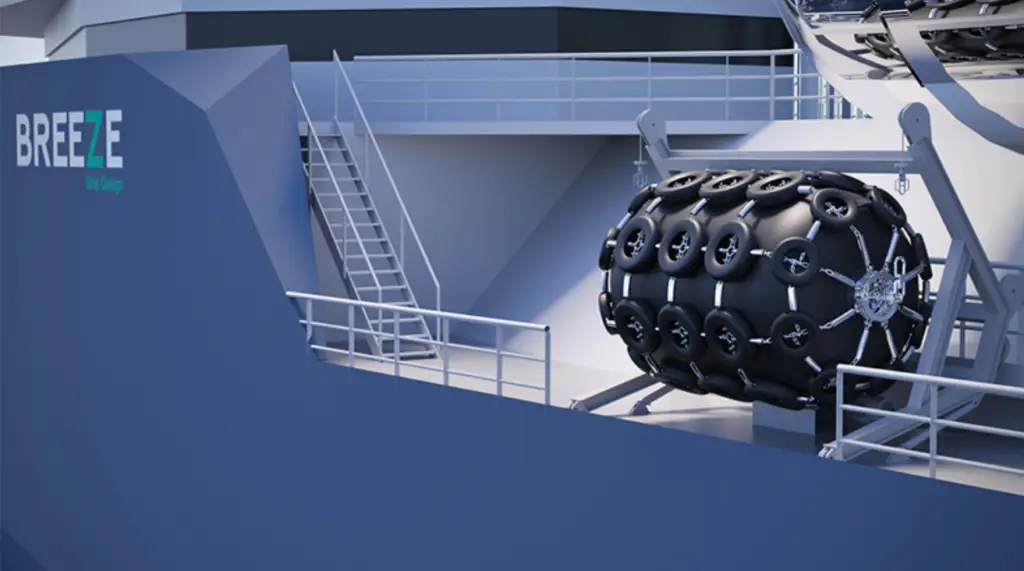

Fender davits

Fender davits are the most efficient and safe way of handling your fenders. A davit, with inbuilt cradle, will store your fenders on deck, ready for deployment and operations. Handling is done from a control panel, or remote control.

Click here to read more about our fender davits

Range:

4.5 x 9.0 m fender – Davit SWL 15 tons

2.0 x 3.5 m fender – Davit SWL 2 tons

2.5 x 4.0 m fender – Davit SWL 3 tons

2.5 x 5.5 m fender – Davit SWL 4 tons

3.3 x 6.5 m fender – Davit SWL 7 tons

Quick release hooks

Quick Release Hooks (QRH) are a vital necessity for safe and efficient jetty mooring operations, particularly at terminals handling and transporting Liquified Natural Gas (LNG), Liquified Petroleum Gas (LPG), chemicals, oil and coal.

Quick Release Hooks (QRH) are a necessity for today’s mooring systems. QRHs enable mooring lines to be secured quickly and safely. The QRH’s are easily released even when loaded to their safe max working limit. Failing mooring lines, failing hooks or structural failure are all too common hazards which can create considerable damage to ships and berths, and disrupt operations – so too great and too expensive a risk to be ignored.

CE, ATEX and EAC available upon requirement

Click here to read more about our Quick Release Hooks

Mooring lines must be able to be safely secured, and quickly and easily released, even when working to a large load limit. By combining Safe Working Load (SWL), material and configuration data with our highly flexible IntMoor QRH products, The Quick Release Hook systems provide a trusted, high quality mooring solution for port owner, port operators and consulting engineers.

Typical applications:

- Container terminals

- Commercial Ro Ro, ferry etc

- Container terminals

- Commercial RoRo, ferry etc.

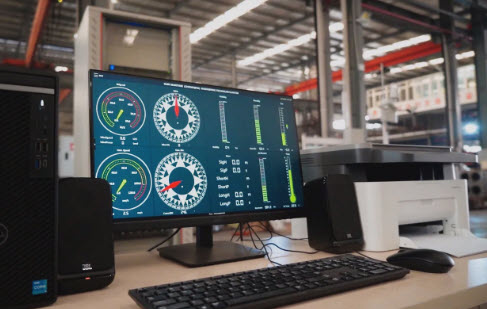

IntMoor Central Monitoring System (CMS) is a centralized monitoring platform that collects and displays real-time data from mooring equipment and sensors in one interface. It provides operators with full situational awareness, alarms for critical loads, and supports safer, more efficient mooring operations.

Safe vessel mooring is dependent on keeping balanced and consistent forces on the mooring lines. The Mooring Load Monitoring System provides constant monitoring of mooring line load and mooring line tension, helping operators avoid safety issues caused by overload or slack conditions.

Features:

- Showing real-time mooring lines load

- Warning and alarm if overload

- Monitoring via PC and mobile devices

- IAS integration if applicable

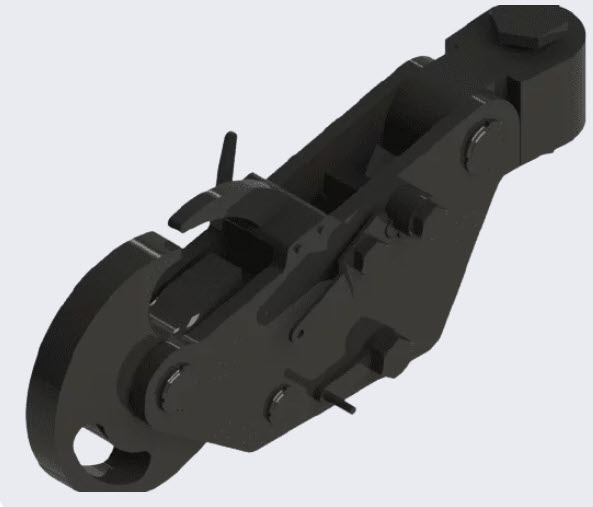

Offshore hooks

Offshore hooks are robust lifting hooks used in offshore and marine operations for safe handling of cargo, tools, and equipment. Built for harsh conditions, they feature high-strength materials, secure safety latches, and compliance with offshore lifting standards. Offshore hooks form a key part of deck equipment, ensuring reliable and controlled lifting during vessel and platform operations.

Click here to read more about our Offshore hooks

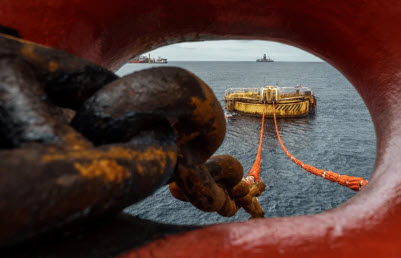

Floating Production Storage and Offloading (FPSO) units are commonly used in offshore oil and gas production for hydrocarbon processing, oil storage and more recently facilitating the production and transportation of liquified natural gas (LNG).

Floating Production Storage and Offloading (FPSO) units are commonly used in offshore oil and gas production for hydrocarbon processing, oil storage and more recently facilitating the production and transportation of liquified natural gas (LNG).

Safety is paramount for the side-by-side mooring of ships, shuttle tankers, and other vessels to an FPSO, especially in the open sea. Managing a safe working load (SWL) ranging between 60 and 600 tons in weight, hooks are usually deployed for tandem or side-by-side mooring.

Developed specifically to meet the demanding requirements of FSO, FPSO, FLNG moorings, The Quick Release Hooks provide resilient and safe mooring for all situations.

The most common safe working load (SWL) for standard Quick release offshore hooks is 200/250 tons, but this could be customized. Release could be manual, local release or remote release (Electrical or hydraulic).

Towing hooks

Marine towing is an activity that requires full knowledge of the dangers inherent in this highly skilled activity. In addition to careful navigation, ships must be confident that their towing equipment is safe and resilient.

Click here to read more about our Towing hooks

Manufactured for exceptional performance, the Quick Release Towing Hooks provides a trusted towing solution for ships, tugboats, harbour, coastal and other marine vessels, even under the harshest marine weather conditions.

Quick Release Towing Hook Applications:

- Towing Vessel

- Tugboat

- Buoy

Deck mounted bollards

Nordic Fender delivers robust deck-mounted bollards engineered for safe and efficient mooring and towing operations. Our portfolio includes standard deck mooring bollards designed in accordance with recognized industry standards, as well as tailor-made solutions for vessels requiring increased Safe Working Loads or application-specific designs.

For bollards intended for quay installations, please refer to the dedicated Bollards section.

Bollards are essential deck fittings designed to secure mooring lines safely and efficiently during berthing operations. Built for high strength and durability, they provide a reliable connection point between the vessel and the quay.

Deck chocks

Chocks are guiding and reinforcing fittings used to lead mooring lines safely between the vessel and shore or offshore structures.

Click here to read more about our Chocks

Designed with smooth, rounded surfaces to reduce abrasion, chocks ensure controlled line handling and protect both the mooring rope and the vessel’s structure. As part of essential deck equipment, chocks play a key role in safe and efficient mooring operations, especially under demanding offshore conditions.

Panama chocks are reinforced fairleads installed at the vessel’s bow, designed in accordance with the mooring requirements set by the Panama Canal Authority.

The Panama chocks are manufactured from high-quality carbon steel castings with smooth rope contact surfaces, and can be supplied with polished areas suitable for synthetic mooring lines.

A complete range of deck-mounted chocks is available with class approvals from major classification societies, including DNV, ABS, BV, LR, CCS and NK.

The choice between single or double chocks depends on vessel size and mooring line diameter. Contact us for guidance in selecting the right solution for your application.

Four Roller Fairleads

DIN 81902 roller fairleads are robust mooring and towing components designed to guide mooring lines safely and efficiently. Manufactured from high-quality cast steel or cast iron, they feature four rollers with smooth, corrosion-protected surfaces to minimize rope wear.

Our DIN 81902 roller fairleads can be supplied to DIN, JIS or GB standards, with class approvals available and custom designs on request.